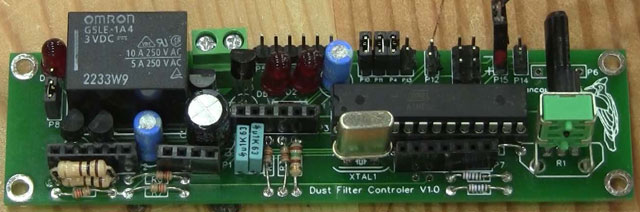

Assembling the module of a controller is pretty easy. Not all the components are required to make it work properly. You only have to solder the components for the fonctions you want to use.

Assembling the module of a controller is pretty easy. Not all the components are required to make it work properly. You only have to solder the components for the fonctions you want to use.

The first thing you need is the power supply for the circuit and the blower’s motor. For that, I used part of an extension and I added a duplex receptable in an electric box. One is always powered and the other one is controlled by the switch and the controller’s relay. You can see it on the diagram below.

Now everything is ready for the circuit’s assembly.

Here are the minimum required components for the controller with an RF remote, with the adjustments with the potentiometer but without the Bluetooth receiver.

Here are the minimum required components for the controller with an RF remote, with the adjustments with the potentiometer but without the Bluetooth receiver.

The R9, R10, R11, R12 and the 5 volt regulator are required for the operation of the RF receiver. If you don’t want it, those components are useless; but be aware that the updates of the firmware will not be accessible because the Bluetooth communication is mandatory to make an update.

I imagine you have seen that the regulators and the transistor are not in the same position that I drew on the circuit board. I made this mistake when I drew it. If I ever have some more made, (other version than 1.0) I will fix it so that they really match all the components. Don’t worry, it’s just a mistake in the drawing; not in the design.

I imagine you have seen that the regulators and the transistor are not in the same position that I drew on the circuit board. I made this mistake when I drew it. If I ever have some more made, (other version than 1.0) I will fix it so that they really match all the components. Don’t worry, it’s just a mistake in the drawing; not in the design.

If you want some light indicators, you will have to add these 3 LEDs and also the 330 Ω resistors. Warning, I know that it’s not easy to see, but the flat parts of the LED are facing the bottom part of the circuit.

If you want some light indicators, you will have to add these 3 LEDs and also the 330 Ω resistors. Warning, I know that it’s not easy to see, but the flat parts of the LED are facing the bottom part of the circuit.

If you don’t want the adjustment with the potentiometer and the RF receiver, here are the minimum required components you need. It’s the exact configuration I use for my second filter which is controlled by my main controller.

If you don’t want the adjustment with the potentiometer and the RF receiver, here are the minimum required components you need. It’s the exact configuration I use for my second filter which is controlled by my main controller.

For the additional modules, you have to install a few connectors to make them work. Here they are with their purpose.

If you want a dust detector, you need this connector and a 150 Ω resistor (R2) plus a 220µF capacitor (C3).

If you also want the small fan to move the dust, you need its connector, its resistor (R6) and its transistor.

If you also want the small fan to move the dust, you need its connector, its resistor (R6) and its transistor.

The relays’ contacts are directly connected to the big J1 connector. The motor’s wires are connected to the same connector as you have seen on the electrical diagram at the top of this document. The brown wires are connected here. All those components are easily found in a hardware store in the electrical section. If you don’t feel at ease with this plan, maybe you’ll need some help from someone familiar with electricity.

The relays’ contacts are directly connected to the big J1 connector. The motor’s wires are connected to the same connector as you have seen on the electrical diagram at the top of this document. The brown wires are connected here. All those components are easily found in a hardware store in the electrical section. If you don’t feel at ease with this plan, maybe you’ll need some help from someone familiar with electricity.

If you want all the possibles options, the circuit has several male connectors for jumpers, depending on the existing options.

First of all, there’s a 3 pin connector to supply the relay. The jumper is not required if you use the good relay; depending on your power supply. Here’s why. To have more versability, I added the R8 resistor. With this resistor, you can use a 5 volt relay with a 75Ω resistor. (Currently it’s a 100Ω in the diagram) But if the relay and the power supply have the same voltage, you only have to short-circuit the two pins with a jumper or a small wire. (in blue)For my controller I’m usingg a 9 volts wall transformer and a 75 Ohms resistor (R8) with the yellow jumper.

First of all, there’s a 3 pin connector to supply the relay. The jumper is not required if you use the good relay; depending on your power supply. Here’s why. To have more versability, I added the R8 resistor. With this resistor, you can use a 5 volt relay with a 75Ω resistor. (Currently it’s a 100Ω in the diagram) But if the relay and the power supply have the same voltage, you only have to short-circuit the two pins with a jumper or a small wire. (in blue)For my controller I’m usingg a 9 volts wall transformer and a 75 Ohms resistor (R8) with the yellow jumper.

Â

Â

Next, there are several jumpers and connectors at the top of the circuit. Let’s begin with the easiest ones. First, the 6 pin connector (P9) which is mostly useless. It only serves for the initial programming of the controller. After it’s programmed, the updates are done through the serial communication port. A special programmer is required to use this connector.

Next, there are several jumpers and connectors at the top of the circuit. Let’s begin with the easiest ones. First, the 6 pin connector (P9) which is mostly useless. It only serves for the initial programming of the controller. After it’s programmed, the updates are done through the serial communication port. A special programmer is required to use this connector.

The P14 and P15 connectors are used to supply the power. Either one of them can be used. The positive faces down on the diagram where you see the + sign.

To the left of the 6 pin useless connector is the P12 connector. It’s the one that supplies the power to the small optional fan that moves the air close to the dust sensor.

Now there’s a series of 4 jumpers. They show to the circuit which options are used by the controller. So let’s go from left to right.

P10 . This jumper shows the presence of a RF receiver model 1096-ADA. No jumper warns the program of the presence of the model 1098-ADA or of the absence of such a receiver. On my second filter, there’s no jumper because I don’t have a RF receiver.

P11. If it’s present, it indicates that the dust sensor is installed. On my main controller I have a P11 jumper but not on the second one.

P4. With this jumper, the circuit knows that there’s a clock module on the circuit. I also have one on my main controller; but not on the second one.

P13. It’s only used to control the speed of the small fan that moves the air around the dust sensor. If the jumper is in place, moving the value of the potentiometer changes the speed. When it’s not in place, varying the potentiometer adjusts the duration of the filtration. Warning. It’s very important to remove this jumper during the normal operation of the controller. Its only purpose is to adjust the speed of the fan.

Needless to say, you will require some external modules like the one for the RF receiver, the HC-06 module for the Bluetooth receiver, a master HC-05 module to transmit to another filter if necessary, a clock module and/or a dust detector.

Needless to say, you will require some external modules like the one for the RF receiver, the HC-06 module for the Bluetooth receiver, a master HC-05 module to transmit to another filter if necessary, a clock module and/or a dust detector.

I know that this seems very complicated for someone who’s not accustomed to electronic circuitry but trust me on this, it’s not that complicated. It’s just like a woodworking project; you take your time to build, one component at a time.